Check Valve Manufacturer in USA

SVR Global is a leading Check valve manufacturer in USA. A check valve serves as a one-way barrier to stop pumped-up water from flowing back into the pipe. The check valve has two openings to preserve fluid flow. Check valves are necessary for both condensate and sump pumps to prevent backflow. The moveable component is forced back into a closed condition when fluid flows in the other direction, stopping the backflow of fluid. Gravity drives the water back into the reservoir without the check valve. SVR Global, the Check valve manufacturer in USA guaranteed free delivery in San Francisco, Chicago, and Boston. They offer a dependable and cost-efficient option for preventing backflow and keeping fluid flow systems secure and effective.

Types:

•Swing Check Valve

•Lift Check Valve

•Ball Check Valve

•Diaphragm Check Valve

•Stop Check Valve

•Dual Plate Check Valve

•Forged Check Valve

Industries:

Check valves are used in marine and shipbuilding applications to prevent backflow in seawater systems, ballast systems, and various fluid transfer systems on ships and offshore structures.

•Fertilizer Industries

•Pulp and Paper industries

•Industrial Chemical Piping Industries

•Oil and gas industries

•Petrochemical industries

•Textile and Process Industries

•Thermal and Nuclear Power industries

Applications:

•Check valves are used in gas pipelines to stop the harmful and equipment-damaging backflow of gases, such as natural gas or other gases.

•In order to prevent the backflow of polluted water into the pure water supply, check valves are utilised in water treatment facilities.

•To regulate fluid flow and stop backflow, check valves are utilised in medical equipment like infusion pumps and respirators.

•Check valves are employed in fire protection systems to stop water or other firefighting materials from flowing backwards, which can reduce the system’s efficacy.

Advantages:

•Low maintenance

•Cost-effective

•Energy efficient

•Reduced noise

•Space-saving

•Improved system efficiency

•Prevents water hammer

•Prevents backflow

•Easy installation

Description:

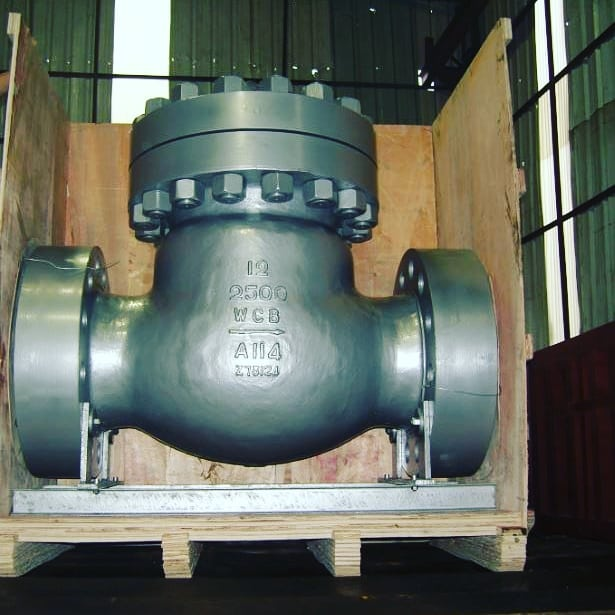

Body Material- Cast steel and cast iron (LF2, A216, WCB, WCC, LCB,LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L,SS904L, CF8, CF8M, F304, F316, F31L, F91), Alloy20 , Hastelloy ALBR, DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22,F304, F316, F91] .

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends- butt weld, flanged, lug, wafer, threaded, socket weld