Knife Gate Valve Manufacturers in USA

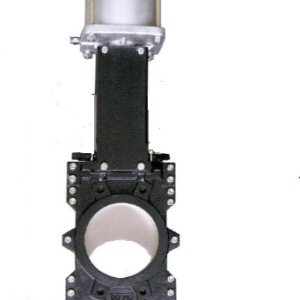

A knife gate valve is a critical isolation valve used in industrial piping systems handling slurry, viscous fluids, and solids-laden media. Designed with a sharp-edged gate, these valves provide reliable shut-off with minimal clogging, making them ideal for harsh and abrasive service conditions.

SVR Global is a leading Knife Gate Valve Manufacturers and Supplier in USA, delivering engineered knife gate valve solutions for mining, pulp & paper, wastewater treatment, power plants, and chemical processing facilities. Our knife gate valves are designed for dependable isolation, smooth operation, and long service life in both standard and severe-service applications.

With extensive experience supporting EPC contractors and plant operators, SVR Global supplies knife gate valves that meet stringent project specifications and international isolation valve standards.

What Is a Knife Gate Valve?

A knife gate valve is a linear motion isolation valve designed to cut through thick fluids, slurries, and solids. The sharpened gate moves vertically to open or close the flow path, allowing effective shut-off in applications where conventional gate valves may clog due to media buildup.

Knife Gate Valve Applications in Industrial Systems

SVR Global knife gate valves are widely used in demanding industrial applications, including:

- Slurry handling and mineral processing systems

- Wastewater and sewage treatment pipelines

- Pulp and paper stock and fiber processing lines

- Power plant ash handling systems

- Chemical and industrial process pipelines

These applications require valves capable of handling abrasive media, solids accumulation, and frequent operation with reliable sealing.

Types of Knife Gate Valves

SVR Global manufactures and supplies a comprehensive range of knife gate valve designs to suit diverse service conditions.

Uni-Directional Knife Gate Valves

Designed for low-pressure applications with flow in a single direction, offering cost-effective isolation.

Bi-Directional Knife Gate Valves

Provide tight shut-off in both flow directions, suitable for higher pressure and demanding slurry services.

Slurry Knife Gate Valves

Specifically engineered for abrasive, solids-laden, and fibrous media in mining and wastewater applications.

Pneumatic Knife Gate Valves

Used for automated and frequent operation in process, utility, and material handling systems.

Industries Served

SVR Global knife gate valves are supplied to industrial projects across the United States, including:

- Mining and mineral processing plants

- Pulp and paper manufacturing facilities

- Wastewater and sewage treatment plants

- Power generation and ash handling systems

- Chemical and industrial processing units

Knife Gate Valve Materials & Standards

Knife gate valves are manufactured using materials selected based on pressure, temperature, and media characteristics:

- Stainless steel knife gate valves for corrosive and chemical services

- Carbon steel knife gate valves for industrial and moderate-pressure applications

- Ductile iron knife gate valves for water and wastewater systems

- Alloy steel knife gate valves for severe-service and abrasive environments

All SVR Global knife gate valves comply with MSS SP-81, ASME B16.34, ANSI, and DIN standards, ensuring compatibility with industrial piping systems and EPC project requirements.

Technical Specifications

- Design Standards: MSS SP-81, ASME B16.34

- End Connections: Wafer, Lug, Flanged

- Size Range: DN50–DN1800

- Pressure Rating: PN10–PN16 / ANSI Class 150

- Temperature Range: Up to +200 °C

- Operation: Manual, Pneumatic, Electric, Hydraulic

- Service: On/off isolation

Inspection, Testing & Certification

All SVR Global knife gate valves undergo rigorous inspection and testing to ensure reliable isolation performance:

- Hydrostatic shell and seat testing

- Functional operation testing

- Visual and dimensional inspection

- Material traceability verification

- EN 10204 Type 3.1 material certification

Special Design Features

- Sharp-edged gate for effective slurry cut-off

- Low pressure drop with unobstructed flow path

- Compact face-to-face dimensions

- Suitable for solids, fibrous, and viscous media

- Low maintenance with robust construction

Why Choose SVR Global as Your Knife Gate Valve Manufacturer in USA?

- Engineered isolation solutions for slurry and abrasive services

- Proven support for mining, wastewater, and power projects

- Compliance with US and international valve standards

- Complete technical documentation and inspection records

- Reliable long-term performance in harsh operating conditions