Simplex Basket Strainer Manufacturer in USA

A simplex basket strainer is a compact filtration device used to remove solid contaminants from liquid pipelines to protect pumps, control valves, meters, and heat exchangers. Designed for single-line operation, simplex basket strainers are widely used where temporary shutdown for cleaning is acceptable and system simplicity is preferred.

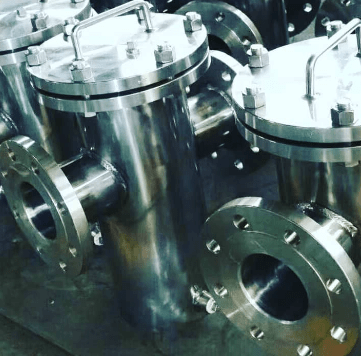

SVR Global is a reliable Simplex Basket Strainer Manufacturer and Supplier in USA, supplying heavy-duty strainer solutions for oil & gas, power generation, chemical processing, marine, and water infrastructure projects. Our simplex basket strainers are engineered for efficient solids removal, low pressure drop, and long-term service reliability in industrial process systems.

With extensive experience supporting EPC contractors, OEMs, and plant operators across the United States, SVR Global delivers simplex basket strainers that comply with project specifications and international standards.

What Is a Simplex Basket Strainer?

A simplex basket strainer consists of a single strainer housing with a removable basket element installed inside the flow path. As fluid passes through the basket, solid particles are trapped while clean fluid continues downstream. For cleaning or basket replacement, the system is isolated and depressurized, allowing safe maintenance.

Simplex basket strainers are commonly installed in systems where continuous operation is not critical and maintenance intervals can be scheduled.

Simplex Basket Strainer Applications in Industrial Systems

SVR Global simplex basket strainers are used in a wide range of industrial applications, including:

- Pump and control valve protection in oil & gas facilities

- Filtration in power plant cooling water and auxiliary systems

- Solids removal in chemical and petrochemical process lines

- Fuel oil, lube oil, and hydraulic systems

- Water transmission, treatment, and industrial utility pipelines

These services require strainers with adequate dirt-holding capacity, structural strength, and ease of maintenance.

Types of Simplex Basket Strainers

SVR Global manufactures and supplies simplex basket strainers in multiple configurations to suit different operating requirements:

Top-Entry Simplex Basket Strainers

Designed for easy basket removal from the top, suitable for high-flow and heavy solid-loading applications.

Side-Entry Simplex Basket Strainers

Compact design suitable for space-constrained installations and lower flow rates.

Temporary and Fine Filtration Basket Strainers

Supplied with interchangeable baskets for coarse or fine filtration based on process cleanliness requirements.

High-Pressure Simplex Basket Strainers

Engineered for high-pressure oil & gas and power generation services requiring robust body construction.

Industries Served

SVR Global simplex basket strainers are supplied to industrial projects across the United States, including:

- Oil & gas production, refining, and pipeline systems

- Power generation and thermal utility plants

- Chemical and petrochemical processing facilities

- Marine and offshore support systems

- Water treatment and industrial utilities

Simplex Basket Strainer Materials & Standards

Simplex basket strainers are manufactured using materials selected according to process media, pressure, temperature, and corrosion requirements:

- Carbon steel simplex basket strainers for oil & gas and utility service

- Stainless steel simplex basket strainers for corrosive and chemical media

- Duplex stainless steel strainers for marine and high-chloride environments

- Alloy steel strainers for high-temperature and severe-service conditions

All simplex basket strainers are produced in compliance with internationally recognized standards such as ASME B16.34, ASME Section VIII (where applicable), ANSI pressure classes, and project-specific EPC requirements.

Technical Specifications

- Design Standards: ASME B16.34, ASME Section VIII

- Flange Standards: ASME B16.5 / ASME B16.47

- End Connections: Flanged, Butt Weld

- Size Range: DN25–DN1200 (1″–48″)

- Pressure Class: ASME Class 150–600

- Filtration Rating: 10 micron to 10 mm

- Basket Type: Perforated / Wire mesh / Wedge wire

- Flow Direction: Horizontal / Vertical

Inspection, Testing & Certification

All SVR Global simplex basket strainers undergo thorough inspection and testing to ensure performance and durability:

- Hydrostatic shell testing

- Visual and dimensional inspection

- Positive Material Identification (PMI)

- Weld inspection and non-destructive testing (RT, UT, MT, PT)

- NACE MR0175 / ISO 15156 compliance for sour service (when required)

- EN 10204 3.1 / 3.2 material test certification

Special Design Features

- High dirt-holding capacity baskets

- Quick-opening covers for simplified maintenance

- Drain and vent connections for safe cleaning

- Low pressure drop internal flow design

- Custom basket mesh and perforation options

Why Choose SVR Global as Your Simplex Basket Strainer Manufacturer in USA?

- Engineered-to-order strainer designs

- Proven reliability in industrial process systems

- Compliance with US and international standards

- Support for EPC, retrofit, and replacement projects

- Complete technical documentation and inspection reports