Strainer Manufacturer in USA

A strainer is a critical pipeline protection component in industrial fluid systems, designed to remove debris, solids, and contaminants before they reach sensitive equipment. Industrial strainers play a vital role in preventing equipment damage, reducing downtime, and maintaining consistent flow performance across process systems.

SVR Global is a leading Strainer Manufacturer and Supplier in USA, delivering engineered strainer solutions for oil & gas, power generation, chemical processing, water infrastructure, and industrial utility projects. Our strainers are designed for reliable debris removal, low pressure drop, and long service life in both standard and severe-service applications.

With extensive experience supporting EPC contractors, utilities, and plant operators, SVR Global supplies industrial strainers that meet stringent project specifications and international piping standards.

What Is a Strainer?

A strainer is a mechanical filtration device installed in a pipeline to remove unwanted solid particles such as rust, scale, sand, and debris from liquids, gases, or steam. By trapping contaminants upstream, strainers protect pumps, control valves, meters, and heat exchangers from clogging, erosion, and premature failure in industrial systems.

Strainer Applications in Industrial Systems

SVR Global strainers are widely used across critical industrial applications, including:

- Oil & gas production, refining, and processing systems

- Power generation plants and cooling water circuits

- Chemical and petrochemical processing facilities

- Water treatment, desalination, and distribution networks

- Industrial utilities and process pipelines

These applications require strainers with high debris-holding capacity, durable construction, and reliable performance under varying pressure and temperature conditions.

Types of Industrial Strainers

SVR Global manufactures and supplies a wide range of strainer configurations to suit diverse process requirements.

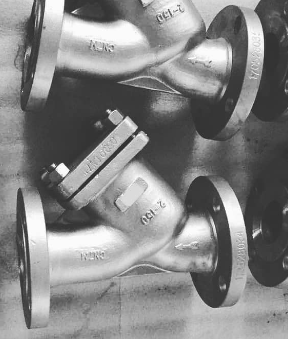

Y Strainers

Compact design suitable for moderate debris removal in liquid, gas, and steam services.

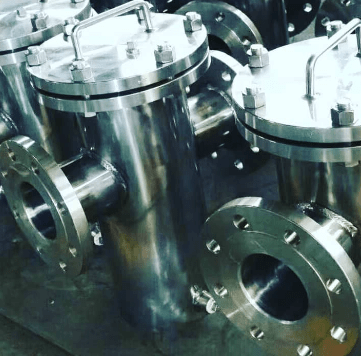

Basket Strainers

High-capacity filtration with low pressure drop for continuous and heavy-duty applications.

Temporary Strainers

Installed during commissioning and startup to protect downstream equipment from construction debris.

Duplex Strainers

Designed for uninterrupted operation, allowing cleaning without stopping system flow.

Industries Served

SVR Global strainers are supplied to industrial projects across the United States, including:

- Oil & gas production and processing facilities

- Power generation and industrial utility networks

- Chemical and petrochemical plants

- Water treatment and distribution infrastructure

- Industrial process and pipeline systems

Strainer Materials & Standards

Industrial strainers are manufactured using materials selected based on pressure, temperature, media compatibility, and service conditions:

- Stainless steel strainers for corrosion-resistant and chemical services

- Carbon steel strainers for high-pressure and high-temperature applications

- Ductile iron strainers for water, utility, and industrial networks

- Alloy steel strainers for severe-service and critical process conditions

All SVR Global strainers comply with ASME B16.34, ANSI, API, and DIN standards, ensuring compatibility with US piping codes and EPC project specifications.

Technical Specifications

- Design Standards: ASME B16.34

- End Connections: Flanged, Threaded, Butt Weld

- Size Range: DN15–DN1200 (½″–48″)

- Pressure Class: ASME Class 150–2500

- Screen Mesh: Customized as per application

- Flow Configuration: Inline

- Operation: Manual cleaning

Inspection, Testing & Certification

All SVR Global strainers undergo rigorous inspection and testing to ensure dependable performance:

- Hydrostatic pressure testing

- Visual and dimensional inspection

- Screen and basket integrity verification

- Positive Material Identification (PMI)

- EN 10204 Type 3.1 / 3.2 material certification

Special Design Features

- Efficient debris removal with minimal pressure drop

- Robust body and screen construction for long service life

- Easy access for cleaning and maintenance

- Custom mesh sizes and perforation options

- Suitable for continuous, critical, and severe-service applications

Why Choose SVR Global as Your Strainer Manufacturer in USA?

- Engineered strainer solutions for critical industrial applications

- Proven support for EPC, utility, and infrastructure projects

- Compliance with US and international piping standards

- Complete technical documentation and inspection records

- Reliable performance in demanding operating conditions