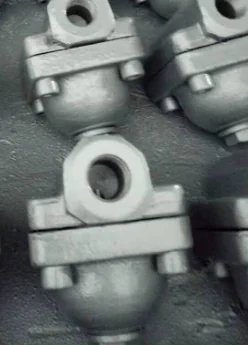

Thermodynamic Steam Trap Manufacturer in Canada

A thermodynamic steam trap is a reliable mechanical device used to automatically discharge condensate and non-condensable gases from steam systems while preventing live steam loss. Operating on the principle of thermodynamic energy differences, these traps are compact, durable, and ideal for high-pressure, intermittent, and variable-load steam applications.

SVR Global is a leading Thermodynamic Steam Trap Manufacturer and Supplier in Canada, providing engineered steam trap solutions for power generation, petrochemical, chemical processing, manufacturing utilities, and industrial steam distribution networks. Our thermodynamic steam traps are designed for stable condensate removal, minimal maintenance, and long service life in both standard and severe-service industrial applications.

With extensive experience supporting EPC contractors, plant operators, and maintenance teams across Canada, SVR Global supplies thermodynamic steam traps that meet strict project specifications and international quality standards.

What Is a Thermodynamic Steam Trap?

A thermodynamic steam trap uses a disc that cycles open and closed based on the velocity and pressure difference between condensate and steam. As condensate enters the trap, the disc lifts to allow discharge. When steam enters, the high-velocity flow creates a pressure differential above the disc, forcing it closed and preventing live steam loss. Once the steam condenses inside the trap, the disc reopens for the next discharge cycle.

Thermodynamic steam traps are suitable for high-pressure mains, drip legs, and tracing lines, providing fast response and low-maintenance operation.

Thermodynamic Steam Trap Applications in Industrial Steam Systems

SVR Global thermodynamic steam traps are used across a wide range of industrial steam systems, including:

- Condensate discharge from steam mains and headers

- Drip legs to remove accumulated condensate

- Steam tracing lines for freeze protection and heat maintenance

- Process equipment such as heat exchangers, turbines, and reboilers

- High-pressure intermittent condensate applications

These applications require traps capable of accurate discharge under variable loads, resistance to water hammer, and reliable operation in outdoor or harsh environments.

Types of Thermodynamic Steam Traps

SVR Global manufactures multiple thermodynamic steam trap designs to suit different process requirements:

Standard Thermodynamic Steam Traps

Compact, versatile traps for general industrial and utility steam applications.

High-Pressure Thermodynamic Steam Traps

Engineered to handle elevated pressure mains and heavy condensate loads.

Outdoor/Weather-Resistant Thermodynamic Steam Traps

Rugged design suitable for outdoor piping and exposed steam systems.

Integral Strainer Thermodynamic Steam Traps

Equipped with built-in strainers to protect the disc and orifice from debris and solids.

Industries Served

SVR Global thermodynamic steam traps are supplied to industrial projects across Canada, including:

- Power generation plants and cogeneration units

- Oil & gas refining and petrochemical facilities

- Chemical processing plants and industrial utilities

- Steam utilities in manufacturing and large campuses

Thermodynamic Steam Trap Materials & Standards

Thermodynamic steam traps are manufactured from materials chosen to withstand pressure, temperature, and process conditions:

- Carbon steel and forged steel bodies for high-pressure service

- Stainless steel internals for corrosion-resistant applications

- Hardened disc and seating surfaces to handle flash steam erosion

- Optional integrated strainers to protect critical internal components

All thermodynamic steam traps are produced in compliance with internationally recognized standards such as ASME B16.34, ANSI pressure classes, and applicable Canadian regulations, ensuring compatibility with EPC and industrial project requirements.

Technical Specifications

- Design Standards: ASME B16.34

- Face-to-Face: ASME B16.10 / ISO 5752

- Flange Standards: ASME B16.5 / ASME B16.47

- End Connections: Flanged, Butt Weld, Socket Weld, Threaded

- Size Range: DN15–DN50 (½″–2″)

- Pressure Class: ASME Class 150–300

- Temperature Range: −50 °C to +300 °C

- Leakage Class: API 598 / ISO 5208 Rate A

- Actuation: Mechanical, self-operating

Inspection, Testing & Certification

All SVR Global thermodynamic steam traps undergo comprehensive inspection and testing to ensure performance and reliability:

- Hydrostatic shell and seat testing as per API 598

- Positive Material Identification (PMI) with ferrite verification

- Functional testing under simulated steam conditions

- Non-destructive examination (UT, RT, MT, PT)

- EN 10204 3.1 / 3.2 material certification

Special Design Features

- Self-operating disc mechanism for intermittent condensate discharge

- Compact, rugged body for high-pressure applications

- Resistance to water hammer and vibration

- Optional integral strainers for debris protection

- Minimal moving parts for long maintenance intervals

Why Choose SVR Global as Your Thermodynamic Steam Trap Manufacturer in Canada?

- Engineered, application-specific steam trap solutions

- Support for EPC, retrofit, and replacement projects

- Compliance with Canadian and international standards

- Complete technical documentation and inspection reports

- Proven long-term performance in industrial steam systems