Through Conduit Knife Gate Valve Manufacturer in USA

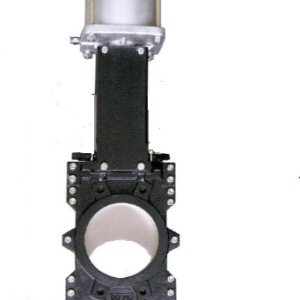

A through conduit knife gate valve is designed to provide unobstructed flow and reliable isolation in pipelines handling slurry, powders, granules, or solid-laden fluids. The full-bore, through-conduit design prevents media buildup inside the valve body, making it suitable for demanding industrial services where blockage and wear are common concerns.

SVR Global is a leading Through Conduit Knife Gate Valve Manufacturer and Supplier in USA, delivering engineered valve solutions for mining, bulk material handling, pulp and paper, wastewater, and industrial slurry pipelines. Our through conduit knife gate valves are built for consistent shutoff, reduced maintenance, and long service life in severe-service applications.

With extensive experience supporting EPC contractors, plant operators, and maintenance teams across Canada, SVR Global supplies through conduit knife gate valves that meet stringent project specifications and international standards.

What Is a Through Conduit Knife Gate Valve?

A through conduit knife gate valve is a linear motion valve that features a straight-through internal passage when fully open, allowing media to pass without obstruction. When closed, the knife-edge gate moves across the flow path to isolate the pipeline. This design eliminates cavities where solids can accumulate, reducing wear, clogging, and maintenance issues in slurry and bulk material systems.

Through Conduit Knife Gate Valve Applications in Industrial Systems

SVR Global through conduit knife gate valves are used across a wide range of industrial applications, including:

- Slurry and tailings pipelines in mining operations

- Bulk material handling systems for powders and granules

- Pulp and paper processing lines

- Wastewater treatment and sludge handling facilities

- Chemical processing systems with solid-laden media

These applications require valves that provide unobstructed flow, reliable isolation, and resistance to abrasion and buildup.

Types of Through Conduit Knife Gate Valves

SVR Global manufactures and supplies through conduit knife gate valves in multiple configurations to suit different process requirements:

Resilient Seated Through Conduit Knife Gate Valves

Provide tight shutoff using elastomer-lined seats for fine slurry or sludge service.

Metal Seated Through Conduit Knife Gate Valves

Designed for high-temperature or highly abrasive media where seat durability is critical.

Heavy-Duty Through Conduit Knife Gate Valves

Reinforced body and gate construction for severe-service and high-wear applications.

Pneumatic and Electric Actuated Through Conduit Knife Gate Valves

Enable automated operation for high-cycle or remote pipeline installations.

Industries Served

SVR Global through conduit knife gate valves are supplied to industrial projects across Canada, including:

- Mining and mineral processing plants

- Bulk material handling and transfer facilities

- Pulp and paper mills

- Wastewater treatment and sludge handling systems

- Chemical processing plants and industrial utilities

Through Conduit Knife Gate Valve Materials & Standards

Through conduit knife gate valves are manufactured using materials selected for abrasion resistance and structural strength:

- Carbon steel and stainless steel bodies for general and corrosive service

- Alloy steels for high-wear and high-temperature applications

- Elastomer or metal seats depending on media characteristics

- Hardened knife-edge gates for extended service life

All valves are produced in accordance with international standards such as API 609, ISO 9001, and ANSI pressure classes, ensuring reliability in demanding industrial environments.

Technical Specifications

- Design Standards: API 609 / ISO 9001

- Face-to-Face: ISO 5752 / EN 558

- Flange Standards: ASME B16.5 / ASME B16.47

- End Connections: Flanged, Wafer, Lug

- Size Range: DN50–DN1200 (2″–48″)

- Pressure Class: ANSI Class 150–300

- Temperature Range: −20 °C to +400 °C

- Actuation: Manual, Pneumatic, Electric

Inspection, Testing & Certification

All SVR Global through conduit knife gate valves undergo comprehensive inspection and testing:

- Hydrostatic shell and seat testing as per API 598

- Visual and dimensional inspection

- Positive Material Identification (PMI)

- Non-destructive testing (UT, RT, MT, PT) where applicable

- Functional testing to verify unobstructed flow and tight shutoff

- EN 10204 3.1 / 3.2 material certification

Special Design Features

- Full-bore through conduit design to prevent media buildup

- Knife-edge gate for cutting through solids

- Reinforced body for abrasive service

- Resilient or metal seat options

- Manual, pneumatic, or electric actuation

- Designed for high-cycle and severe-service operation

Why Choose SVR Global as Your Through Conduit Knife Gate Valve Manufacturer in USA?

- Engineered valve solutions for slurry and bulk solids service

- Support for EPC, retrofit, and replacement projects

- Compliance with Canadian and international standards

- Complete technical documentation and inspection reports

- Proven long-term performance in severe industrial applications