Globe Valve Manufacturer in USA

A globe valve is a critical flow-control component used in industrial piping systems where precise regulation and throttling are required. Its linear motion design allows accurate control of flow rate, pressure, and temperature, making it essential for demanding process environments.

SVR Global is a leading Globe Valve Manufacturer and Supplier in USA, delivering precision-engineered globe valve solutions for oil & gas, power generation, chemical processing, water infrastructure, and industrial utility projects. Our globe valves are designed for tight shutoff, stable throttling performance, and long service life under high-pressure and high-temperature conditions.

With extensive experience supporting EPC contractors, plant operators, and OEMs, SVR Global supplies globe valves that comply with stringent project specifications and internationally recognized industry standards.

Quick Definition: A globe valve is a linear motion valve used to regulate fluid flow by moving a disc perpendicular to a stationary seat, providing precise throttling and reliable shutoff.

What Is a Globe Valve?

A globe valve is a linear motion valve used to regulate or throttle fluid flow in a pipeline. Flow control is achieved by moving a disc perpendicular to a stationary seat, allowing precise modulation of flow and dependable shutoff. Globe valves are preferred in applications where accurate control and repeatable performance are essential.

Where Are Globe Valves Used in Industrial Systems?

SVR Global globe valves are widely used across critical industrial flow systems, including:

- Flow regulation in oil & gas production, refining, and pipeline systems

- Steam, feedwater, and pressure control in power generation plants

- Process control in chemical and petrochemical facilities

- Water transmission and industrial utility networks

- Process industries requiring accurate throttling and stable flow control

These applications demand valves with dependable sealing, erosion resistance, and consistent control characteristics under varying operating conditions.

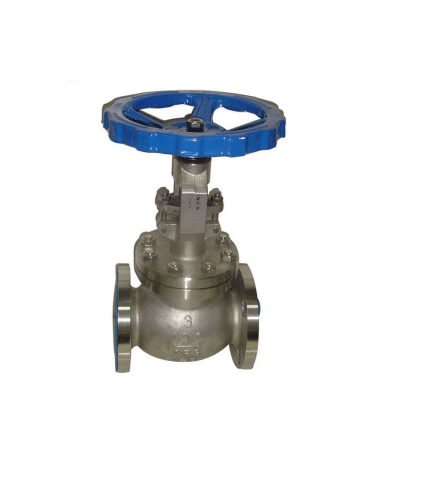

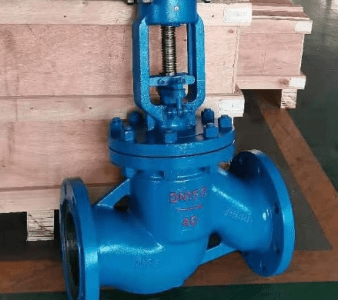

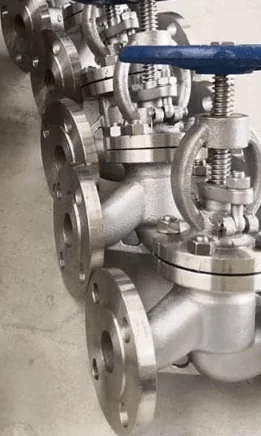

Types of Globe Valves

SVR Global manufactures and supplies a comprehensive range of globe valve designs to suit diverse operating conditions:

T-Pattern Globe Valves

Standard globe valve design used for throttling and isolation in general industrial services.

Y-Pattern Globe Valves

Designed to reduce pressure drop, making them suitable for high-pressure and high-temperature applications.

Angle Globe Valves

Used where flow direction changes are required, ideal for high-velocity and erosive services.

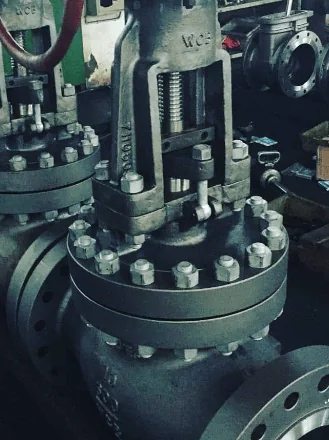

Pressure Seal Globe Valves

Engineered for high-pressure and high-temperature applications, commonly used in power generation and boiler systems.

Bellows Sealed Globe Valves

Provide zero external leakage performance, making them ideal for hazardous, toxic, or expensive media.

Industries Served

SVR Global globe valves are supplied to industrial projects across the United States, including:

- Oil & gas production, refining, and pipeline infrastructure

- Power generation and steam control systems

- Chemical and petrochemical processing plants

- Water transmission and industrial utilities

- Process industries requiring precise flow regulation

Globe Valve Materials & Standards

Globe valves are manufactured using high-quality materials selected based on pressure, temperature, and media compatibility:

- Stainless steel globe valves for corrosion-resistant and chemical services

- Carbon steel globe valves for high-pressure and high-temperature applications

- Ductile iron globe valves for water distribution and utility networks

- Alloy steel globe valves for severe-service and critical process applications

All SVR Global globe valves comply with API 602, API 603, API 623, ASME B16.34, ANSI, and DIN standards, ensuring reliable throttling performance and compatibility with EPC and industrial piping systems.

Technical Specifications

- Design Standards: API 623, ASME B16.34

- Face-to-Face: ASME B16.10

- Flange Standards: ASME B16.5 / ASME B16.47

- End Connections: Flanged, Butt Weld, Socket Weld

- Size Range: DN15–DN1200 (½″–48″)

- Pressure Class: ASME Class 150–2500

- Temperature Range: −50 °C to +538 °C

- Leakage Class: API 598 / ISO 5208

- Operation: Manual, Gear, Pneumatic, Electric

Inspection, Testing & Certification

All SVR Global globe valves undergo rigorous quality control procedures to ensure performance and compliance:

- Hydrostatic shell and seat testing as per API 598

- Positive Material Identification (PMI)

- NACE MR0175 / ISO 15156 compliance for sour service (where applicable)

- Non-destructive examination (UT, RT, MT, PT) as required

- EN 10204 Type 3.1 / 3.2 material certification

Special Design Features

- Accurate throttling and stable flow modulation

- High-pressure and high-temperature capability

- Bellows-sealed options for zero external leakage

- Anti-cavitation and low-noise trim designs

- Fire-safe construction for critical service

- Maintenance-friendly design with replaceable internal components

Globe Valve vs Other Valve Types

Globe Valve vs Gate Valve

Globe valves provide precise throttling control, while gate valves are primarily used for full open or full close isolation.

Globe Valve vs Ball Valve

Ball valves are suitable for on-off service, whereas globe valves enable accurate and repeatable flow regulation.

Globe Valve vs Butterfly Valve

Butterfly valves are compact and economical for large diameters, while globe valves offer superior control accuracy for throttling applications.

Why Choose SVR Global as Your Globe Valve Manufacturer in USA?

- Engineered globe valve solutions for critical process control applications

- Proven support for EPC, retrofit, and replacement projects

- Compliance with US and international valve standards

- Complete technical documentation and inspection records

- Reliable performance in high-pressure and severe-service environments

Request a Quote or Speak with a Globe Valve Engineer to discuss your application requirements and valve selection.

Globe Valve FAQs

What is a globe valve used for?

Globe valves are used to regulate and control flow in pipelines where precise throttling and stable control are required.

How does a globe valve work?

The disc moves perpendicular to the seat, changing the flow area and allowing accurate control of fluid movement.

Which globe valve is suitable for high-pressure service?

Pressure seal and Y-pattern globe valves are recommended for high-pressure and high-temperature applications.

Can globe valves be used in corrosive environments?

Yes. Stainless steel, duplex, or alloy materials can be selected based on fluid compatibility and corrosion resistance requirements.