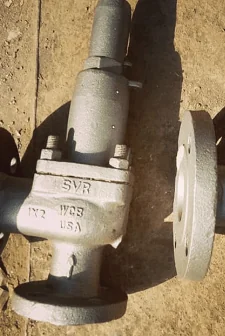

Safety Valve Manufacturer in USA

A safety valve is a critical pressure protection device used in industrial systems to automatically relieve excess pressure and prevent equipment damage, process failure, or safety hazards. Reliable overpressure protection is essential for maintaining safe operations across high-pressure process environments.

SVR Global is a leading Safety Valve Manufacturer and Supplier in USA, delivering engineered safety valve solutions for oil & gas, power generation, chemical processing, steam systems, and industrial utilities. Our safety valves are designed to provide accurate set pressure, rapid opening response, and dependable reclosing performance in both standard and severe-service applications.

With extensive experience supporting EPC contractors, plant operators, and OEMs, SVR Global supplies safety valves that comply with stringent project specifications and international safety standards.

Quick Definition: A safety valve is an automatic pressure relief device that protects pressurized systems by rapidly releasing excess pressure when a preset limit is exceeded.

What Is a Safety Valve?

A safety valve is an automatic pressure relief device designed to release excess pressure from a system when it exceeds a predetermined set point. Once system pressure returns to a safe operating range, the valve recloses automatically, ensuring continuous protection against overpressure, equipment damage, and operational hazards.

Where Are Safety Valves Used in Industrial Systems?

SVR Global safety valves are widely used across critical industrial pressure systems, including:

- Overpressure protection in oil & gas production, refining, and pipeline systems

- Steam pressure relief in power generation boilers and thermal systems

- Pressure protection in chemical and petrochemical processing units

- Safety relief for pressure vessels, compressors, and storage tanks

- Equipment protection in industrial utilities and process plants

These applications require valves with fast response time, reliable sealing, and strict compliance with regulatory safety codes.

Types of Safety Valves

SVR Global manufactures and supplies multiple safety valve designs to suit different pressure relief requirements:

Spring-Loaded Safety Valves

Commonly used for steam, gas, and liquid service. These valves offer reliable operation and accurate set pressure across a wide range of industrial applications.

Pilot-Operated Safety Valves

Designed for high-pressure and high-capacity systems, offering superior stability and reduced pressure fluctuations near set pressure.

Conventional Safety Valves

Direct-acting safety valves suitable for general industrial pressure relief applications.

Balanced Bellows Safety Valves

Engineered for systems with variable back pressure, maintaining consistent performance and accurate pressure relief.

Industries Served

SVR Global safety valves are widely supplied to industrial projects across the United States, including:

- Oil & gas production, refining, and pipeline systems

- Power generation boilers and steam systems

- Chemical and petrochemical processing plants

- Pressure vessels, compressors, and storage tanks

- Industrial utilities and critical process equipment

Safety Valve Materials & Standards

Safety valves are manufactured using robust materials selected to withstand high pressure, temperature, and corrosive environments:

- Stainless steel safety valves for corrosive and high-temperature services

- Carbon steel safety valves for steam, gas, and high-pressure process applications

- Alloy steel safety valves for severe service and elevated temperature conditions

- Bronze safety valves for low-pressure and utility applications

All SVR Global safety valves are designed and manufactured in compliance with API 520, API 526, ASME Section VIII, and ANSI pressure classes, ensuring adherence to global pressure relief and safety regulations.

Technical Specifications

- Design Standards: ASME Section VIII, API 526, API 527

- Set Pressure Range: As per ASME code requirements

- Pressure Class: ASME Class 150–2500

- Size Range: DN15–DN400 (½″–16″)

- Temperature Range: −50 °C to +538 °C

- Discharge Coefficient: As per API 526

- End Connections: Flanged, Threaded

- Operation: Spring-loaded / Pilot-operated

Inspection, Testing & Certification

All SVR Global safety valves undergo rigorous inspection and testing to ensure safety, accuracy, and compliance:

- Set pressure and blowdown testing

- Seat tightness testing as per API 527

- Hydrostatic pressure testing

- Positive Material Identification (PMI)

- NACE MR0175 / ISO 15156 compliance for sour service

- Non-destructive examination (UT, MT, PT)

- EN 10204 Type 3.1 / 3.2 material certification

Special Design Features

- Accurate and repeatable pressure relief performance

- Fast opening and controlled reclosing response

- Balanced designs for systems with variable back pressure

- Fire-safe construction for critical applications

- High-cycle fatigue-resistant springs

- Tamper-proof sealing to maintain set pressure integrity

Why Choose SVR Global as Your Safety Valve Manufacturer in USA?

- Engineered safety valve solutions for critical applications

- Proven support for EPC, retrofit, and replacement projects

- Compliance with US and international safety standards

- Complete technical documentation and inspection reports

- Reliable performance in high-pressure and severe-service environments

Request a Quote or Speak with a Safety Valve Engineer to discuss your application and compliance requirements.