Steam Trap Manufacturer in USA

A steam trap is a critical component in industrial steam systems, designed to automatically discharge condensate, air, and non-condensable gases while preventing the loss of live steam. Proper steam trap selection improves thermal efficiency, protects equipment, and ensures stable and safe steam operation.

SVR Global is a leading Steam Trap Manufacturer and Supplier in USA, delivering high-performance steam trap solutions for oil & gas, power generation, chemical processing, and industrial steam distribution systems. Our steam traps are engineered to enhance energy efficiency, reduce operating costs, and provide reliable condensate removal in both standard and severe-service applications.

With proven experience supporting EPC contractors, utilities, and plant operators, SVR Global supplies steam traps that comply with stringent project specifications and international steam system standards.

What Is a Steam Trap?

A steam trap is an automatic valve installed in steam systems to remove condensate, air, and non-condensable gases without allowing live steam to escape. By maintaining correct steam quality and pressure, steam traps help prevent water hammer, improve heat transfer efficiency, and extend the service life of steam equipment.

Steam Trap Applications in Industrial Steam Systems

SVR Global steam traps are widely used across critical steam applications, including:

- Steam distribution and condensate recovery systems

- Power plant boilers and auxiliary steam lines

- Oil & gas refineries and process heating systems

- Chemical and petrochemical processing plants

- Industrial utilities and heat transfer systems

These applications require steam traps with dependable operation, high thermal efficiency, and long service life under varying pressure and load conditions.

Types of Steam Traps

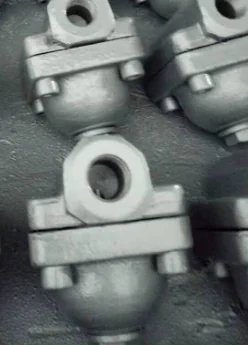

SVR Global manufactures and supplies a complete range of steam trap types to meet diverse system requirements.

Thermodynamic Steam Traps

Compact and robust design, ideal for high-pressure steam applications and superheated steam lines.

Float and Thermostatic (F&T) Steam Traps

Provide continuous condensate discharge with excellent air venting, suitable for process equipment and heat exchangers.

Thermostatic Steam Traps

Operate based on temperature difference, commonly used in steam tracing lines and low-load systems.

Inverted Bucket Steam Traps

Durable construction for handling high pressure and heavy condensate loads in industrial steam systems.

Industries Served

SVR Global steam traps are supplied to industrial facilities across the United States, including:

- Oil & gas refineries and processing plants

- Power generation and boiler systems

- Chemical and petrochemical facilities

- Industrial utilities and process heating systems

- Steam distribution and condensate recovery networks

Steam Trap Materials & Standards

Steam traps are manufactured using materials selected based on steam pressure, temperature, and service conditions:

- Stainless steel steam traps for corrosion-resistant and hygienic applications

- Carbon steel steam traps for high-pressure and high-temperature steam service

- Cast iron steam traps for low- to medium-pressure utility systems

- Alloy steel steam traps for severe-service and power plant applications

All SVR Global steam traps comply with ASME B16.34, API, ANSI, and DIN standards, ensuring compatibility with industrial steam networks and EPC project requirements.

Technical Specifications

- Design Standards: ASME B16.34

- End Connections: Flanged, Threaded, Socket Weld

- Size Range: ½″–2″

- Pressure Rating: Up to ASME Class 1500

- Temperature Range: Up to +425 °C

- Discharge Type: Intermittent or continuous

- Application: Steam, condensate removal, air venting

Inspection, Testing & Certification

All SVR Global steam traps undergo comprehensive inspection and testing to ensure reliable field performance:

- Hydrostatic pressure testing

- Functional performance and discharge testing

- Leak and sealing verification

- Visual and dimensional inspection

- EN 10204 Type 3.1 material certification

Special Design Features

- Efficient condensate removal without loss of live steam

- Improved energy efficiency and reduced operating costs

- Protection against water hammer and thermal shock

- Robust construction for long service life

- Suitable for high-pressure and critical steam applications

Choose SVR Global as Your Steam Trap Manufacturer in USA?

- High-performance steam trap solutions for industrial steam systems

- Proven support for EPC, power plant, and refinery projects

- Compliance with US and international steam standards

- Complete technical documentation and inspection records

- Reliable long-term operation in demanding steam conditions