Check Valve Manufacturers in USA

A check valve is an essential flow-control component used in industrial piping systems to automatically prevent reverse flow and protect equipment from backflow damage. Reliable non-return protection is critical for maintaining system integrity, operational efficiency, and equipment safety in pressurized process environments.

SVR Global is a leading Check Valve Manufacturers and Supplier in USA, delivering precision-engineered check valve solutions for oil & gas, water infrastructure, chemical processing, power generation, and industrial utility projects. Our check valves are designed for reliable sealing, low pressure drop, and long service life in both standard and severe-service applications.

With extensive experience supporting EPC contractors, plant operators, and OEMs, SVR Global supplies check valves that meet stringent project specifications and internationally recognized standards.

Quick Definition: A check valve, also called a non-return valve, is a one-way valve that allows flow in a single direction and automatically prevents reverse flow to protect pumps, pipelines, and downstream equipment.

What Is a Check Valve?

A check valve, also known as a non-return valve, is a mechanical valve that allows fluid flow in one direction while automatically preventing reverse flow. It operates without external actuation, relying solely on fluid velocity and pressure to open and close. This protects pumps, compressors, pipelines, and downstream equipment from backflow-related damage and pressure surges.

Where Are Check Valves Used in Industrial Systems?

SVR Global check valves are widely used across critical industrial flow systems, including:

- Backflow prevention in oil & gas pipelines and processing units

- Pump and compressor protection in water treatment and distribution networks

- Flow direction control in power generation and cooling systems

- Process protection in chemical and petrochemical plants

- Non-return protection in industrial utilities and pumping stations

These applications demand valves with fast response, dependable sealing, and minimal pressure loss to maintain system efficiency and safety.

Types of Check Valves

SVR Global manufactures and supplies a wide range of check valve designs to suit different flow conditions and service requirements:

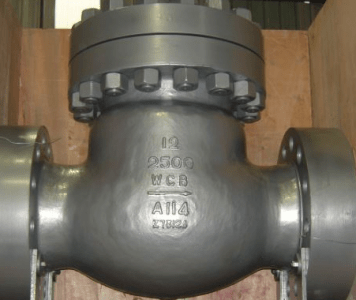

Swing Check Valves

Feature a pivoting disc design suitable for low to medium pressure systems and large-diameter pipelines.

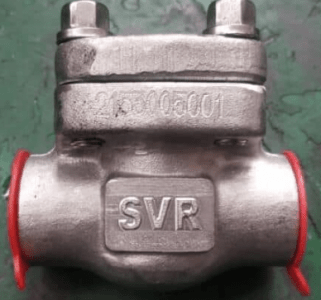

Lift Check Valves

Operate with vertical disc movement, offering precise sealing and suitability for high-pressure applications.

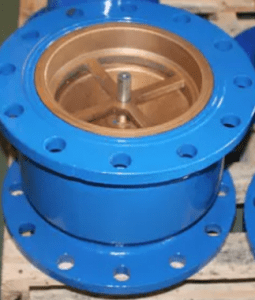

Wafer Check Valves

Compact, lightweight valves designed for installation between flanges in space-constrained piping systems.

Ball Check Valves

Simple and durable design, commonly used in low-pressure and slurry applications where debris tolerance is required.

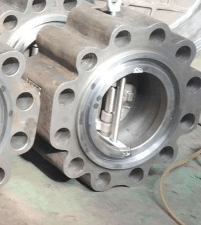

Dual-Plate / Dual-Disc Check Valves

Designed for quick closing, low pressure drop, and high-flow applications, helping to reduce water hammer risk in critical systems.

Industries Served

SVR Global check valves are widely supplied to industrial projects across the United States, including:

- Oil & gas production, refining, and pipeline systems

- Water treatment, desalination, and distribution networks

- Power generation plants and cooling systems

- Chemical and petrochemical processing facilities

- Industrial utilities and pumping stations

Check Valve Materials & Standards

Check valves are manufactured using high-quality materials selected based on pressure, temperature, and media compatibility:

- Stainless steel check valves for corrosive and chemical services

- Carbon steel check valves for high-pressure and high-temperature applications

- Ductile iron check valves for water supply and utility networks

- Alloy steel check valves for severe service and power generation applications

All SVR Global check valves comply with API 6D, ASME B16.34, ANSI, DIN, and international piping standards, ensuring compatibility with EPC and industrial system requirements.

Technical Specifications

- Design Standards: API 6D, ASME B16.34

- Face-to-Face: ASME B16.10 / ISO 5752

- Flange Standards: ASME B16.5 / ASME B16.47

- End Connections: Flanged, Butt Weld, Socket Weld

- Size Range: DN15–DN1200 (½″–48″)

- Pressure Class: ASME Class 150–2500

- Temperature Range: −50 °C to +400 °C

- Leakage Class: API 598 / ISO 5208 Rate A

- Operation: Flow-driven, automatic

Inspection, Testing & Certification

All SVR Global check valves undergo comprehensive inspection and testing to ensure reliable performance:

- Hydrostatic shell and seat testing as per API 598

- Positive Material Identification (PMI)

- NACE MR0175 / ISO 15156 compliance for sour service (where applicable)

- Non-destructive examination (UT, RT, MT, PT) as required

- EN 10204 Type 3.1 / 3.2 material certification

Special Design Features

- Automatic one-way flow protection to prevent backflow

- Low pressure drop designs for improved energy efficiency

- Durable disc and seat materials for extended service life

- Quick-closing dual-plate designs to reduce water hammer

- Maintenance-friendly construction with replaceable internals

- High-temperature and corrosion-resistant configurations for demanding services

Why Choose SVR Global as Your Check Valve Manufacturer in USA?

- Engineered non-return valve solutions for critical applications

- Proven support for EPC, retrofit, and replacement projects

- Compliance with US and international design and testing standards

- Complete technical documentation and inspection records

- Reliable performance in high-pressure and severe-service environments

Request a Quote or Speak with a Check Valve Engineer to discuss your application requirements and valve selection.