Electric Actuated Valve Manufacturer in USA – SVR Global

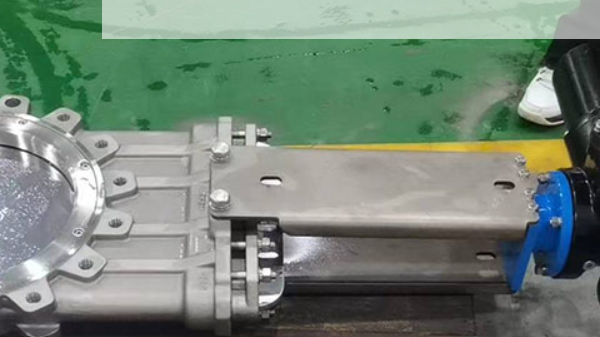

SVR Global is a specialized Electric Actuated Valve Manufacturer in USA, offering a wide portfolio of automated valves designed for precision, reliability, and ease of operation. Our electric actuated valves combine high-performance valve bodies with robust actuators engineered to meet demanding industrial standards across oil & gas, power generation, water treatment, marine, and chemical processing industries.

Function & Working

Electric actuated valves utilize an electric motor to provide automated operation for opening, closing, or modulating flow. Unlike pneumatic or manual operation, electric actuation delivers accurate positioning with feedback control, remote operation through digital/analog signals, reduced maintenance compared to pneumatic systems, and silent, smooth operation even under continuous duty cycles. Actuators are available in quarter-turn (ball, butterfly, plug) and linear motion (globe, gate, control) configurations, ensuring compatibility with multiple valve types.

Advantages

Wide torque range from 35 Nm to 50,000 Nm

Available in on/off, modulating, and fail-safe designs

Equipped with limit switches, torque sensors, and manual override

Weatherproof & explosion-proof enclosures (IP67, IP68, NEMA 4/4X/7/9)

Energy efficient and suitable for remote or hazardous locations

Actuator Specifications

| Parameter | Range / Options |

|---|---|

| Voltage Options | 24V AC/DC, 110V AC, 220V AC, 380V AC, 415V AC |

| Frequency | 50 Hz / 60 Hz |

| Operating Speed | 18 RPM – 96 RPM (depending on actuator model & torque requirement) |

| Duty Cycle | S2 – 30 min, S4 – up to 1200 starts/hour |

| Torque Output | 35 Nm – 50,000 Nm |

| Protection | IP67 / IP68 weatherproof, Explosion-proof (ATEX/IECEx certified) |

| Control Signal | 4–20 mA, 0–10V, Modbus, Profibus, HART |

| Temperature Range | –25°C to +70°C (optional low-temperature execution up to –60°C) |

| Position Feedback | Potentiometer, encoder, or smart position transmitters |

| Manual Override | Handwheel or declutch lever for emergency operation |

Materials Offered

| Component | Materials & Grades |

|---|---|

| Body | WCB (ASTM A216), LCB, Stainless Steel (CF8, CF8M, F304, F316), Ductile Iron, Cast Iron |

| Disc/Ball | Stainless Steel (F304/F316), Duplex, Super Duplex, Inconel, Monel |

| Seat | PTFE, RPTFE, Metal-to-Metal (Stellite, TC) |

| Stem | AISI 410, SS316, Duplex, Inconel |

Industries Served

Oil & Gas Pipelines & Refineries

Power Generation (Thermal, Hydro, Nuclear)

Water & Wastewater Treatment Plants

HVAC & District Cooling

Chemical & Petrochemical Plants

Marine & Offshore Applications

Technical Specifications

| Category | Details |

|---|---|

| Design Standards | API 6D, ISO 5211, ASME B16.34, EN 15714 |

| Pressure Ratings | Class 150 – 1500, PN10 – PN250 |

| Size Range | DN15 – DN1200 |

| End Connections | Flanged (RF/RTJ), Butt Weld (BW), Socket Weld (SW), Threaded (NPT/BSP) |

| Actuation Options | On/Off, Modulating, Failsafe (spring return or capacitor backup) |