Alloy 20 Valve Manufacturer in USA

Alloy 20 valves are selected for corrosive services where conventional stainless steels fail to provide adequate resistance. As an Alloy 20 Valve Manufacturer in USA, SVR Global manufactures industrial valves for sulphuric acid, phosphoric acid, chlorides, and aggressive chemical process applications where material stability is critical to long-term plant reliability.

Alloy 20 (UNS N08020) is a nickel-iron-chromium alloy with copper and molybdenum additions, developed specifically to resist sulphuric acid attack, pitting, and stress corrosion cracking. Valves produced in this material are commonly used in continuous corrosive duty where predictable corrosion rates and consistent sealing performance are required.

Alloy 20 Valves for Corrosive Chemical Process Systems

Alloy 20 valves are installed in systems where acids and chloride-bearing fluids are stored, transferred, or processed continuously. Typical installations include chemical reactors, acid circulation loops, fertilizer production units, and specialty chemical processing lines.

In these systems, valves must isolate or regulate flow without suffering rapid corrosion, pitting, or stress cracking that could compromise pressure integrity. Proper Alloy 20 valve selection ensures stable operation during startup, steady-state service, and long-term continuous exposure.

Corrosion Resistance of Alloy 20 Valves in Acid Service

Alloy 20 valve performance depends on how effectively the alloy resists general corrosion, localized attack, and stress corrosion cracking under varying acid concentrations and temperatures.

During operation, Alloy 20 valves must withstand:

- Continuous exposure to sulphuric and phosphoric acids

- Variable acid concentrations and temperature cycles

- Chloride contamination in mixed chemical streams

- Long-term immersion without loss of mechanical strength

The alloy’s balanced nickel, chromium, copper, and molybdenum content allows it to maintain uniform corrosion behavior and predictable service life in these conditions.

Why Standard Stainless Steel Valves Fail in Acid Service

Conventional stainless steels such as 304 and 316 are not suitable for many acid services and typically fail due to:

- Rapid general corrosion in sulphuric acid

- Localized pitting in chloride-bearing environments

- Stress corrosion cracking under tensile load

- Loss of sealing integrity due to material thinning

Alloy 20 valves are engineered specifically to address these failure modes through controlled chemistry, heat treatment, and corrosion-resistant microstructure.

Advantages of Alloy 20 Valves

- High resistance to sulphuric and phosphoric acids

- Improved protection against pitting and crevice corrosion

- Stable performance in continuous corrosive duty

- Reduced maintenance and replacement frequency

- Long service life in critical chemical process systems

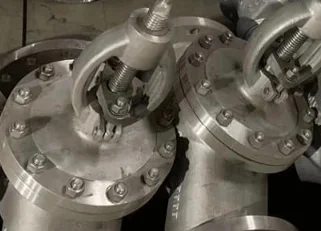

Types of Alloy 20 Valves

- Alloy 20 Ball Valve – Used for quick on-off isolation in corrosive chemical pipelines.

- Alloy 20 Butterfly Valve – Applied in large-diameter piping for isolation in low to medium pressure corrosive service.

- Alloy 20 Check Valve – Prevents reverse flow in acidic and chloride-bearing process systems.

- Alloy 20 Gate Valve – Used for full-bore isolation where minimal pressure drop is required in corrosive service.

- Alloy 20 Globe Valve – Applied for throttling and flow regulation in corrosive process applications.

How to Select the Right Alloy 20 Valve for Corrosive Service

Correct valve selection is essential for safe and reliable corrosive service. Parameters typically evaluated include:

- Type and concentration of acid handled

- Operating temperature range

- Presence of chlorides or mixed chemicals

- Isolation or control function

- Pressure class and leakage requirements

- Manual or actuated operation

Improper selection can result in accelerated corrosion, leakage, or unsafe performance during continuous operation.

Alloy 20 Material Grades and Standards

Alloy 20 valve materials must meet strict chemical composition and heat treatment requirements to ensure corrosion resistance.

| Material | Grade | Standard | Typical Applications |

|---|---|---|---|

| Nickel Alloy | Alloy 20 (CN7M) | ASTM A351 / A743 | Cast valve bodies for acid service |

| Nickel Alloy | Alloy 20 | ASTM A182 (where specified) | Forged pressure parts |

| Nickel Alloy | UNS N08020 | UNS | Unified Alloy 20 designation |

| Nickel Alloy | 2.4660 | EN / DIN | European Alloy 20 equivalent |

Industrial Applications of Alloy 20 Valves

- Sulphuric acid production and transfer systems

- Chemical processing and batch reactors

- Fertilizer and phosphoric acid plants

- Specialty acid circulation loops

- Metal pickling and surface treatment units

- Chloride-bearing chemical process lines

Design Standards and Testing Requirements for Alloy 20 Valves

Alloy 20 valves are designed and tested in accordance with applicable standards, including:

- ASME B16.34 for pressure–temperature ratings

- API 600 / API 602 for gate valve design

- API 6D / API 608 for ball valve design

- API 594 for check valves

- API 598 for pressure and leakage testing

- ISO 5208 for leakage classification

Valves typically undergo hydrostatic, seat leakage, and functional testing prior to delivery.

SVR Global assists engineering teams with Alloy 20 valve selection based on service medium, acid concentration, operating temperature, pressure class, and installation requirements. Support includes material compatibility review, design standard compliance, and suitability assessment for corrosive process service.