Control Valve Manufacturers in USA

A control valve is a critical component in automated industrial systems, used to precisely regulate flow, pressure, temperature, or liquid level within a process. Accurate control of these variables is essential for process stability, safety, and efficiency across modern industrial operations.

SVR Global is a leading Control Valve Manufacturers and Supplier in USA, delivering engineered control valve solutions for oil & gas, offshore, power generation, chemical processing, and water infrastructure projects. Our control valves are designed for reliable modulation, consistent performance, and long service life in both standard and severe-service applications.

With extensive experience supporting EPC contractors, system integrators, and plant operators, SVR Global supplies control valves that meet stringent project specifications and international standards.

What Is a Control Valve?

A control valve is the final control element in a process control loop. It automatically adjusts its opening in response to signals from a controller, allowing precise regulation of flow, pressure, temperature, or level within a system.

Where are Control Valves Used? (Industrial Applications)

- Flow control in oil & gas pipelines and process units

- Pressure regulation in power plant steam and condenser systems

- Temperature control in chemical reactors and heat exchangers

- Level control in water transmission and industrial treatment facilities

- Automated process control in offshore platforms and marine systems

Which Type of Control Valves should you choose?

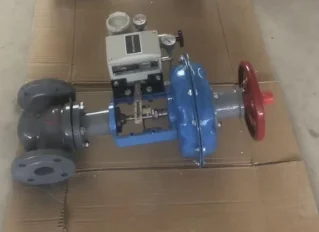

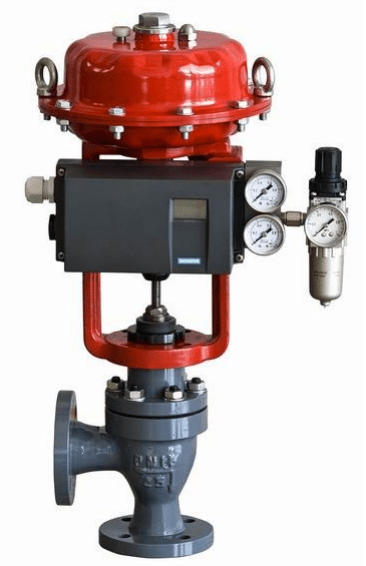

Globe Control Valves

Designed for precise throttling and accurate flow regulation in high-pressure and high-temperature service.

Ball Control Valves

Provide fast response, tight shutoff, and reliable modulation for automated flow control.

Butterfly Control Valves

Compact and lightweight valves suitable for large-diameter and space-constrained installations.

Angle Control Valves

Used in severe-service applications involving flashing, cavitation, or erosive media.

Control Valve Materials & Standards

- Stainless steel control valves for corrosive services

- Carbon steel control valves for high-pressure applications

- Duplex and super duplex valves for offshore environments

- Alloy steel valves for high-temperature service

All control valves comply with API 6D, ASME B16.34, ISA standards, and ANSI pressure classes.

Technical Specifications

- Size Range: DN15–DN1200

- Pressure Class: ASME 150–2500

- Temperature Range: −50 °C to +300 °C

- Actuation: Manual, Pneumatic, Electric, Hydraulic

Inspection, Testing & Certification

- Hydrostatic testing as per API 598

- PMI and NACE MR0175 compliance

- Fire-safe and fugitive emission testing

- EN 10204 certification

Special Design Features

- Anti-blowout stem design

- Metal-seated and anti-cavitation trims

- Extended stem and emergency sealant options

Why Choose SVR Global?

- Engineered-to-order solutions

- EPC and project support

- International standards compliance

- Complete documentation