Control Valve Manufacturers in USA

A control valve is a critical component in automated industrial systems, used to precisely regulate flow, pressure, temperature, or liquid level within a process. Accurate control of these variables is essential for process stability, safety, and efficiency across modern industrial operations.

SVR Global is a leading Control Valve Manufacturers and Supplier in USA, delivering engineered control valve solutions for oil & gas, offshore, power generation, chemical processing, and water infrastructure projects. Our control valves are designed for reliable modulation, consistent performance, and long service life in both standard and severe-service applications.

With extensive experience supporting EPC contractors, system integrators, and plant operators, SVR Global supplies control valves that meet stringent project specifications and international standards.

What Is a Control Valve?

A control valve is the final control element in a process control loop. It automatically adjusts its opening in response to signals from a controller, allowing precise regulation of flow, pressure, temperature, or level within a system.

Where are Control Valves Used? (Industrial Applications)

- Flow control in oil & gas pipelines and process units

- Pressure regulation in power plant steam and condenser systems

- Temperature control in chemical reactors and heat exchangers

- Level control in water transmission and industrial treatment facilities

- Automated process control in offshore platforms and marine systems

Which Type of Control Valves should you choose?

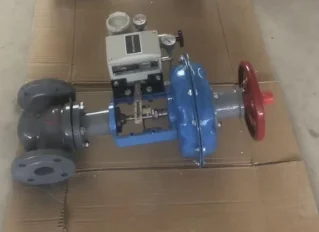

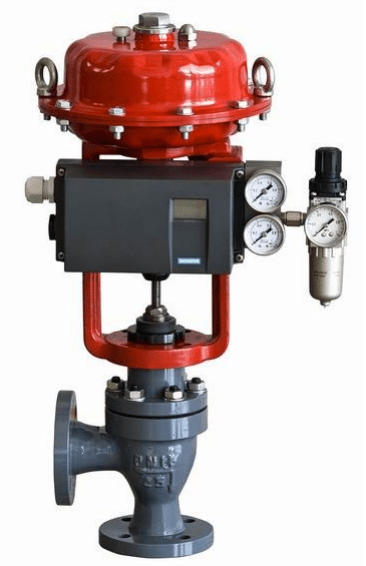

Globe Control Valves

Designed for precise throttling and accurate flow regulation in high-pressure and high-temperature service.

Ball Control Valves

Provide fast response, tight shutoff, and reliable modulation for automated flow control.

Butterfly Control Valves

Compact and lightweight valves suitable for large-diameter and space-constrained installations.

Angle Control Valves

Used in severe-service applications involving flashing, cavitation, or erosive media.

Control Valve Materials & Standards

- Stainless steel control valves for corrosive services

- Carbon steel control valves for high-pressure applications

- Duplex and super duplex valves for offshore environments

- Alloy steel valves for high-temperature service

All control valves comply with API 6D, ASME B16.34, ISA standards, and ANSI pressure classes.

Technical Specifications

- Size Range: DN15–DN1200

- Pressure Class: ASME 150–2500

- Temperature Range: −50 °C to +300 °C

- Actuation: Manual, Pneumatic, Electric, Hydraulic

Inspection, Testing & Certification

- Hydrostatic testing as per API 598

- PMI and NACE MR0175 compliance

- Fire-safe and fugitive emission testing

- EN 10204 certification

Special Design Features

- Anti-blowout stem design

- Metal-seated and anti-cavitation trims

- Extended stem and emergency sealant options

Control Valve vs Other Valve Types

Control Valve vs Gate Valve

Gate valves are used for isolation, while control valves provide precise flow regulation.

Control Valve vs Ball Valve

Ball valves are mainly on-off valves, while control valves support modulation.

Control Valve vs Butterfly Valve

Butterfly valves are compact, but control valves offer higher accuracy.

Why Choose SVR Global?

- Engineered-to-order solutions

- EPC and project support

- International standards compliance

- Complete documentation

FAQs

What is a control valve used for?

It regulates flow, pressure, temperature, or level in industrial systems.

How does a control valve work?

A control valve receives input from a controller and modulates its opening through an actuator and positioner to maintain desired process conditions.

Which control valve is suitable for oil and gas applications?

Globe and ball control valves are commonly used due to their ability to handle high pressure, temperature, and precise flow control.

What actuation options are available for control valves?

Control valves can be supplied with manual, pneumatic, electric, or hydraulic actuators depending on automation and process requirements.

What is the difference between a control valve and an on-off valve?

On-off valves are used for isolation, while control valves provide continuous and precise regulation of process variables.